Eye Wash.

In the event of an eye accident involving chemicals, eyesight can be lost in just a few seconds. That’s why immediate access to the right eye wash is critical. Here you’ll find a complete range of eye wash solutions – from Cederroth’s buffered fluid that neutralises acids and alkalis, to convenient pocket bottles and complete wall‑mounted stations. For cold workplaces, we also offer insulated heated cabinets that keep the fluid frost‑free. Equip your workplace in accordance with regulatory requirements and ensure employee safety.

Choosen filters

How to choose the right eye wash

Choosing an eye wash is not just about volume, but about function. Depending on the risks present in your workplace—such as dust, acids, alkalis or splinters—different types of preparedness are required.

Buffered vs. Saline Solution – What’s the difference?

This is the most important point to understand.

- Buffered eye wash (Cederroth): If corrosive acids or alkalis (e.g. lime, cement, battery acid) get into the eye, simple rinsing is not enough. You need to neutralise the pH value. Cederroth’s eye wash is borate‑buffered, meaning it restores the eye’s pH much faster than water or saline. This is often critical to saving eyesight.

- Saline solution: Best suited for flushing out dust, debris and minor contamination. It does not neutralise chemicals but works well for mechanical cleansing.

Station or Pocket Model?

In many cases, you need both.

- Pocket model (235 ml): Carried on a belt or in a pocket by staff working in risk areas. The purpose is to start flushing immediately while moving toward a larger station.

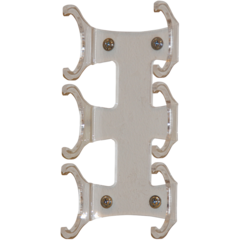

- Wall‑mounted station (500 ml x 2): In chemical accidents, at least 15 minutes of flushing is often recommended. A fixed station with dual bottles ensures sufficient flushing time and allows both eyes to be rinsed simultaneously while waiting for emergency services.

Heated cabinets for cold environments

Eye wash fluid must not freeze. In cold warehouses, sawmills, construction sites or outdoor environments, a heated cabinet is a necessary investment. The cabinet keeps the solution at a suitable temperature (approx. 20°C), ensuring it is ready for immediate use even in sub‑zero conditions.

Check the expiration date

Eye wash is a sterile product with a limited shelf life (typically 4–5 years). An expired bottle is no longer sterile and should be replaced immediately. Replacement bottles can be found under the category /din-url-till-refillFirst Aid Refills.

Guide: First Aid for the Eyes

In many industries, there is an increased risk of eye injuries. Examples of such workplaces include commercial kitchens in restaurants, workshop and industrial facilities, construction sites, laboratories and cleaning companies. To minimise the risk of permanent damage, it is important that proper eye protection equipment is always readily available.

How to stop a corrosive eye injury

If an accident occurs and corrosive substances (acids or alkalis) get into the eyes, time is your greatest enemy. Follow these steps immediately:

-

Start rinsing immediately: The effect is greatest during the very first seconds. Do not hesitate – run to the nearest station.

-

Rinse generously: Ensure the flow is strong. It is crucial that the eye is kept open during rinsing, even if the natural reflex is to close it. Use your fingers to force the eyelids apart.

-

Rinse for a long time: Rinse for at least 15 minutes after exposure to corrosive substances. One bottle is usually not enough. Use several bottles or continue rinsing at a fixed supply unit.

Important: Always seek medical attention after a chemical accident. Bring several bottles of eye wash so you can continue rinsing continuously during transport to the hospital.